FROM QUARRY TO SLAB PROCESSING

The best Roman Travertine in Tivoli

TRAVERTINE SLABS ... and beyond!

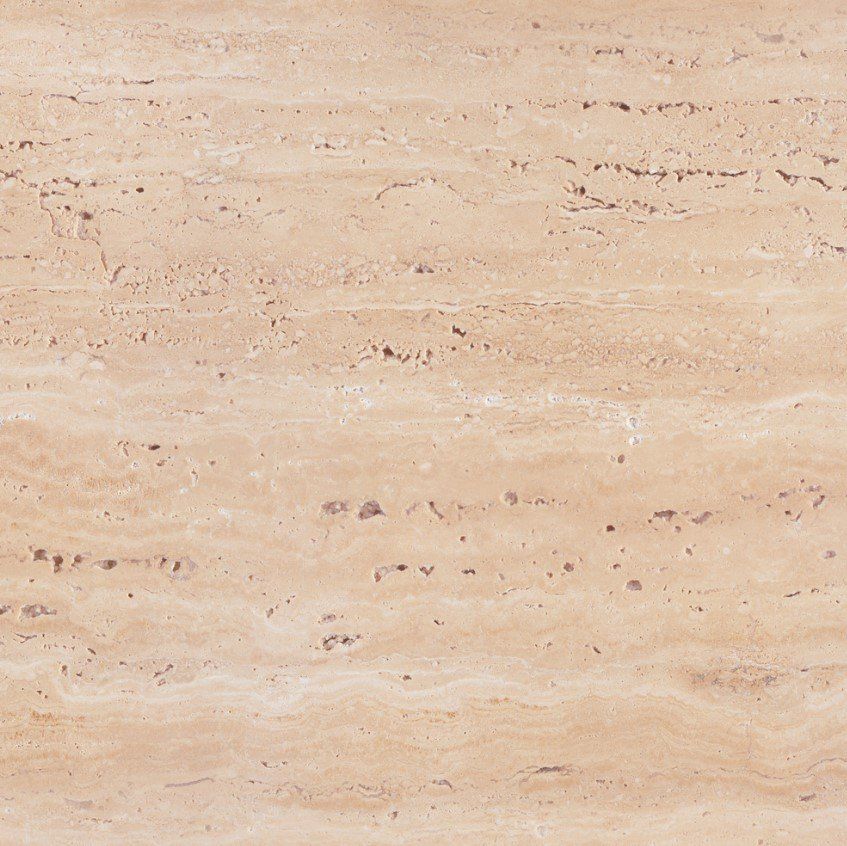

The colour of the travertine depends mainly on the variety of sedimentary position and on the type of oxides it has incorporated - it can therefore range from milky white to hazelnut, through various chromatic shades of yellow and even red. It is more or less compact with evident stratification, fossil imprints are fairly common and it is characterised by a porous, vacuolar, cavernous structure, largely due to the cavities left by the plants of the

basins fed by these waters which then decomposed. During processing, these cavities will be suitably filled, levelled and uniformed to the surface of the stone by grouting.

Despite its granular structure, travertine has uniform mechanical strength and considerable resistance to atmospheric agents. It is a fairly resistant, docile and anti-freeze stone. Receptive to polishing, it is used both for flooring and for the cladding of vertical surfaces both indoors and outdoors, as well as the facades of entire buildings and in urban centres for recovery and redevelopment. It also lends itself well to being sculpted and is also used in the creation of simpler sculptures or decorative elements such as balustrades, handrails or fireplaces.

EXTRACTION The first processing

Once the wall to be cut and demolished in the quarry has been identified, we proceed with the dividing process by choosing the cuts to be made to extract the blocks that will subsequently be selected according to the characteristics of the travertine. The blocks can be supplied shapeless, as they are, or squared for selling slabs that are more uniform in size and suitable for use in the same project. The travertine block is sawn to obtain slabs of various thicknesses and sizes while the direction of the cut strongly affects the external appearance of the stone, thus obtaining products with a completely different aesthetic appearance even when starting from the same block.

If we look at a block of stone, it will be easy to notice the stratifications given by the overlapping of geological layers over the centuries. If, at the time of cutting, the blades follow the stratifications, the block will be cut in the pitch (cross cut): the material will show a more marked shading between one slab and another, and the typical "clouds" will be more visible. If, on the other hand, the blades cut the block perpendicularly to the stratifications, the material is said to be in counter-flap (vein cut): the pieces will be more uniform with each other, with a slight color gradation within the single piece, and streaks will be more marked.

The slab format is the most commercialised type of cut. The slabs have large dimensions compared to their thickness and can be obtained with two different methods: splitting or sawing. With the first method, elements of variable shape, size and thickness are obtained and with sawing, on the other hand, regular and modular elements of specific sizes and thicknesses are obtained. The latter can be applied on different types of support, both traditional and prefabricated, of mortars, adhesives or dowels, up to the most innovative systems in which the travertine elements are adhered to metal frames or even prefabricated concrete panels. At the end of the sawing process, the overall quality is assessed and stored in the yard pending any subsequent processing commissioned or for sale in the raw state. The marketing of travertine and its products can take place during each stage of processing.

GROUTING SURFACES & FINISHES

The grouting of Roman travertine is a necessary process to make the material waterproof and then allow it to be finished as desired. Flat surfaces, straight or shaped edges can be grouted. Filling is achieved by sprinkling the material with a liquid which is then subsequently dried by completely covering the holes and sealing them to perfection. Depending on the substance used, a different visual effect will be obtained. Cement, mastic and resin grouting are the most common. Travertine can be smoothed, polished, carved, bevelled, shaped, sandblasted and antiqued by brushing, to obtain a product with the desired final result.

CONSTANT TERRITORIAL EXPANSION

Cega is established throughout the Lazio and national territory thanks to the best wholesale supply of marble and the like. We are constantly expanding and evolving, including towards the emerging countries of the Middle East.

Enter your details below and we will contact you as soon as possible.